| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : Lishang Precision Machinery

Model Number : LS-1370L

Certification : CE ISO

Place of Origin : Shenzhen China

MOQ : 1

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 500/month

Delivery Time : 15-30days

Packaging Details : durable case

Name : Vertical Machining Center

Brand : Lishang

Type : Vertical machine center

Axis : X/Y/Z

X/Y/Z Three-axis travel : 2500mm/2000mm/1000mm

Size : 2500×1600mm

Machine weight : 33000kg

Gantry width : 2000mm

cutting feed rate : 10-7000mm/min

Repeatability : ±0.01

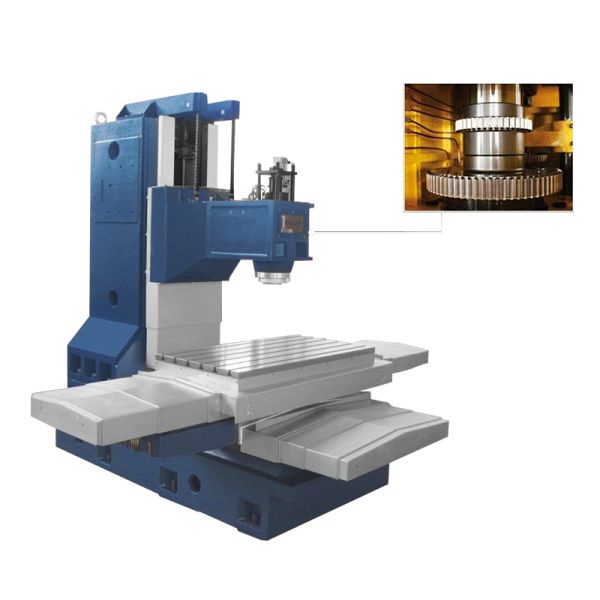

Industrial-grade precision equipment processing LS-1370L large heavy-duty gear cutting processing center

It is a large-scale industrial-grade heavy-cutting gear hard rail machining center that focuses on precision instrument parts and mold processing. The equipment adopts a hard rail structure that can achieve earthquake resistance, stability, durability, and maintain good accuracy under high-intensity cutting conditions.

The equipment has a weighing capacity of up to 1000kg, which can provide stable protection for large-scale cutting. At the same time, the spindle speed is 6000rpm, which ensures the speed during processing and improves the overall efficiency. Precision, heavyweight, high efficiency and speed have become a highlight of the LS-1370L heavy-cutting gear hard rail machining center, bringing convenience to manufacturing companies.

Product specification

| Name | Unit | LS-1370 |

| Workbench working range | mm | 710×1400 |

| Three-axis travel (X/Y/Z) | mm | 1300/700/650 |

| Distance from spindle center to vertical guide rail | mm | 785 |

| Distance from spindle end to worktable | mm | 150-800 |

| Workbench T-slot | 5-18×152.5 | |

| Spindle taper | BT50/φ155 | |

| Maximum spindle speed | rpm | 6000 |

| Spindle motor | kw | 15.0 |

| X-Y-Z axis motor | kw | 3 |

| X-Y ball screw diameter | mm | φ50 |

| Z ball screw diameter | mm | φ50 |

| X-Y-Z fast movement | m/min | 16/16/12 |

| Cutting feed rate | mm/min | 1~8000 |

| Positioning accuracy | mm | ±0.004/300 |

| Repeat positioning accuracy | mm | ±0.0025 |

| Workbench load-bearing | kg | 1000 |

| Total weight of machine tool | T | 9 |

Product Feature

Processing workpiece

Factory real display:

Application

1. Regularly check the hard rails to maintain good rigidity and wear resistance, which can reduce machine wear and tear.

2. Operate strictly within the equipment parameter range to avoid overload operation and damage to the equipment

3. Regularly maintain key components such as the spindle to ensure stable performance, high-speed cutting capability and machining accuracy

4. Please read the operation manual and professional instructions before use to avoid damage to the equipment caused by operating errors.

Sales service

* Instructions for use: Online operating instructions and usage videos are available, and on-site training requires additional fees

* Online guidance: Professional engineers provide online technical guidance to quickly solve customer problems

* Provide 3-year warranty and lifetime technical support services

What's your main products of your company?

We mainly produce and sell various types of CNC machining centers, including vertical machining centers, gantry machining centers, horizontal machining centers, five-axis machining centers, profile machining centers, etc. We have our own factory to support customization and welcome factory inspections.

What is the minimum order quantity?

Minimum order is one piece but a 30% deposit is required.

What payment methods are supported?

T/T , Alibaba, Paypal, USDT, Alipay, Wechat, etc

Which type shipment way ?

About shipment that we have own deliver way like sea method or truck method .

|

|

Industrial Precision CNC Vertical Machining Center LS-1370L Gear Cutting Processing Center Images |